Bethge AG owns the most modern machine park in Europe, which includes all finishing processes for cotton processing or their blends in the textile industry.

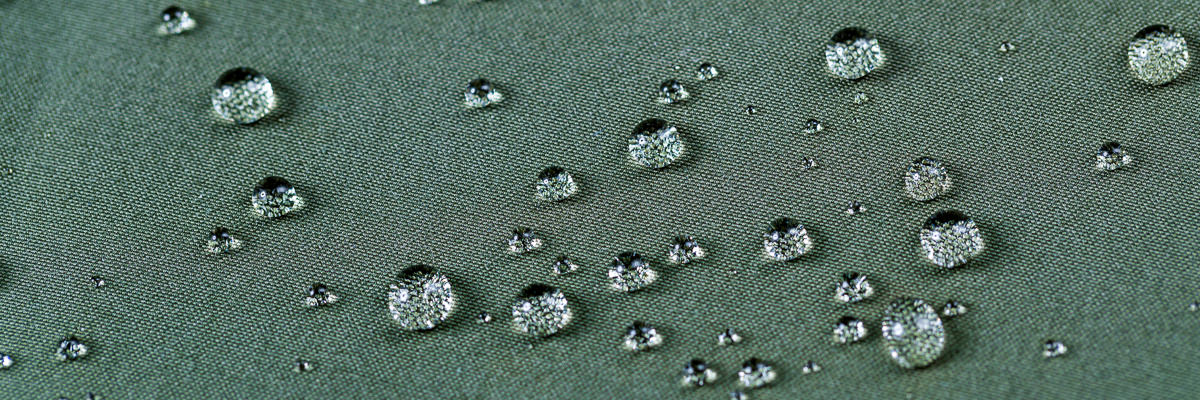

The demands on textiles are diverse. Whether elegant sheen, special weave structures or heat-resistant properties with the highest level of comfort : we refine textiles for our customers according to their wishes.

The following methods are available to give your textiles the properties you need. These can be combined as required. Our experts will be happy to advise you in order to develop the optimal manufacturing process for you.